Private Technology

|

|

| |

“Quality is more important than quantity. One home run is much better than two doubles.”

|

A famous quote which was once said by the late Steve Jobs and this cannot be more true.

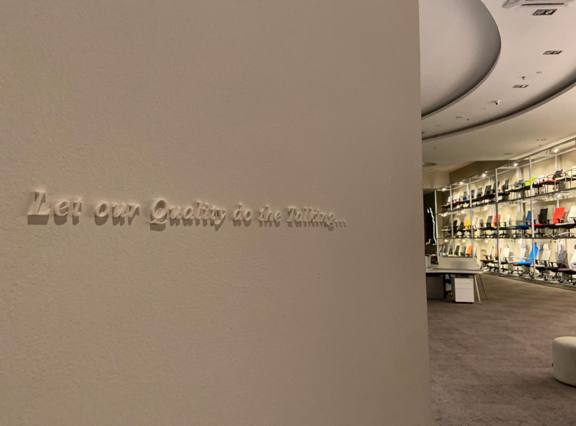

We have always put quality as an indispensable aspect in our products, ever since our establishment in 1999.You would have seen the picture above if you followed our social media pages, and that actually has a deeper meaning behind it. We have adopted an avant garde method to bring across an imperative notion to our visitors in our Malaysia showroom of what determines true and real high quality. |

| |

| |

|

|

We feel that quality are often times diminished and undervalued by the price of the product.

However, if you were to scrutinise more, actively feel, and understand it better, you will then realise and experience the real and true high quality of the product, and why it ensues to be at the stated price.

Just like if you did not pay attention to the wall, you would have just walked past and not realise that there was anything on it. And at the end of the day, this shrouded interpretation would not be passed onto you, and it would be a loss from your visit.

We have always made it a habit to create products of best quality for our customers, maintain the discipline as a company and give all our attention and time to ensure that our products do not fall short of and that important specific processes and checks are done. |

|

| |

| |

| This is what makes us confident to have our motto as “Let Our Quality Do The Talking” and continue to strive and grow as a whole. |

|

| |

Let us explain the technologies used to produce your chair, and how did it come to be the quality it is.

To allow you to understand how the price and quality of the products came to be, we have to explore the production process, and what tools and machines we use to create the masterpiece. |

|

|

|

|

| |

|

|

First and foremost, it is important to note that we manufacture our own products, which means we design, develop parts of the product and assemble them.

For instance, Foam, which is one of the essential parts of a chair, is made from scratch. We utilise a Polyurethane Foam Dispensing Machineto make polyurethane foams for the chair seats. The polyurethane liquid is dispensed out by an injector at high pressure, onto a specific mould casting of a chair seat.

This whole process resembles the making of waffle, which requires the liquid to form into a solid structure. After a solid foam is formed, the worker in charge would then progress to dissipate all the air bubbles that are formed inside the foam. This ensures the springiness of the foam.

Foams that are of bad quality will be rejected and cast away.

The main reason we make our own foam is because this allows us to control the production process and quality better to suit our own set of requirements and criteria for the foam to be used. |

|

| |

|

|

| |

In an era where technologies are advancing at a rapid speed, processes have become automated. Now, with this advantage of Command & Control (C&C), there is no need for manual work as we utilize a High Speed Digitized Cutting Systemto attain the most accurate dimensions and shapes from a big piece of upholstery.

The laser beam would proceed to cut up the desired shapes in perfect measurements via controls from the computer. |

|

|

|

|

| |

|

|

Not forgetting, we also utilize a High Speed Digital Cutting Systemto cut up the relevant shapes of chair seats from a big piece of wood delivered from our supplier by blade.

This system also takes advantage of C&C system, where just one worker in charge is needed to control the whole process.

Just a side note, woods that we use are very distinct as they need to meet certain standardization and conditions before it can be used. With that being said, plywoods we used are marked with Conformité Européenne().

By using both of these systems, there is no need for workers to cut manually. This not only prevents human error, but increases the safety of the workers.

In addition, with more precise cuts, the upholstery can be better sewn onto the chair with exact fitting, and producing a neat and aesthetically pleasing look on the chair as there are no extra bits that is protruding out of the chair. |

|

|

| |

Also, the plywood can be cut perfectly to its intended shapes and sizes, ensuring that the backrest of the chairs are all at the correct measurements.

Plywoods are vacuumed by our Dust Collector Machineduring the filing process to make sure small bits of sharp wood are collected.

This can prevent any potential injuries that may happen to our users, and also our workers during production. |

|

|

|

|

| |

|

|

Speaking of sewing, we also utilize Electric Sewing Machinesimported from many different countries such as Taiwan, Korea, Japan, Czech Republic and many more. The reason being, different types of upholstery requires different sewing methods that are gentle enough to poke through to prevent damages.

For example, leather is one of the more delicate upholstery that require a special sewing machine so it will not break apart. In this case, we use Durkopp Adler imported from Czech Republic to sew.

Not forgetting, the quality of the upholstery also plays a part in the sewing process. We will make sure that our upholstery are of high quality and long-lasting. For instance, the leathers we use are imported from Italy.

This will ensure that all of the upholstery are nicely sewed and the stitches are hard-wearing. |

|

|

| |

At the final process of packaging the finished product, Auto Packing System With Roller Conveyoris used to better secure the parcel that is sent out to you, for better protection and also to prevent any potential loss of parts.

With the automated packing system, it will give workers more time to do other checks on the products. |

|

|

|

|

| |

|

|

Even before packaging, quality checks are made for each specific chair with different requirements, such as dimensions, height and condition of the chair.

We also conduct comprehensive checking on the chair to prevent defects.

During quality checks, the chairs will undergo a cleaning process where each and every one of them is sprayed with cleansing solution.

For chairs to be at the stated price, it depends on the parts and the process to create one whole item.

Parts can be imported from different countries, or even manufactured with specific tools and most appropriate machines, processes also include quality checking and hygiene assurance on chair.

A case in point, the mechanisms we use are imported from Italy, Taiwan and others, selectively for a specific chair. As such, prices differ from one another. However, quality is always maintained at the highest level, regardless of whatever chairs. |

|

|

| |

|

| |

| Hence, Trust Benithem with your office chairs, as we promise you that we will and have always made a conscious effort to produce the best quality products that you haven’t seen. Let our product deliver the unspoken truth of our quality. |

|

|

| |

Let Our Quality Do The Talking.

|

| |

View our office chairs:

|

|

|

| |